What is a QRA?

A QRA is a technical analysis done on Major Hazard Installations (i.e Petrochemicals, Oil and Gas etc) to identify risks to the businesses due to their hazardous activities and substances. A QRA presents risks as below (in quantitative values):

- Likelihood of Major Accident Events Occurring

- Probability of fatality (Personnel Risk) of on-site and offsite (societal – if applicable) personnel

- Extent of consequences of released hazard from the source of release

Why is a QRA needed?

For Industries a QRA might be needed under the following circumstances:

- Legal requirements, where local governments require corporations to demonstrate that their operating risks towards employees and society are within legal / ALARP limits.

- Corporate requirements, where companies / investors make calculated risk evaluations and prioritise risk management activities / investments.

What are the contents of a QRA?

These are the information commonly found in a QRA study report:

- Identification of Hazards / Major hazards associated with the facility being assessed

- Identification of major events from the hazards identified and their probability of occurrence

- Personnel risk calculation given commonly in the following forms

- LSIR – Location Specific Individual Risk – The risk of fatality faced by a person by being present at a specific location in the facility. These values represent comparative risks between locations in the facility being assessed.

- IRPA – Individual Risk Per Annum – Risk of fatality upon an individual of a specific worker group (e.g: Operator, supervisor) by being present in the facility (assumed being present throughout the year). This is the value used to demonstrate if the fatality risks at the facility / society surrounding are tolerable. The values are normally compared with published tolerable risk values (i.e: OSHA, UK HSE, etc)

- PLL-Potential Loss of Life – The possibility of fatality within a worker group factoring in their presence and occupancy in the facility. These values are also comparative values between different worker groups

- Representation of consequences of the major events assessed, which commonly consist of:

- Toxic release

- Fire

- Explosion

- Unignited Release

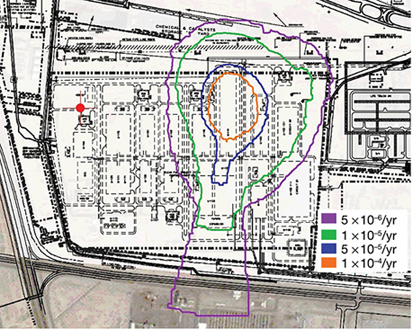

- The above are normally expressed as contours indicating effect/severity distance from the event source. An Example below shows fireball intensity across distance. Each contour shows different intensity (the shorter the distance, the higher the intensity and probability of fatality within the region). With the absence of the probability calculations, these charts normally indicate worst case scenarios (subject to assumptions made in the modelling and QRA mathematical inputs). These charts, can be helpful for sites to organize and structure their ERP to improvise the sites preparation in facing major accident hazards.

- Any recommendations for the facility to implement to demonstrate that their risks are ALARP

How a QRA can be used?

A QRA Report is more than just a document to satisfy the authorities. There are more uses of the QRA report provided it has been prepared with adequate thoughts and technical clarity. A QRA can be useful as:

- Reference in identifying major threats to the business and asset;

- Reference in organizing a site’s emergency preparedness (being prepared for the worst case scenario); and

- Technical data for cost benefit analysis when a major business / safety investment has to be taken by the company to improvise safety.

Does your site need a QRA?

If your facility could be quantified as a Major Hazard Site by the local Laws and Regulations, you are likely under the obligation to prepare a QRA for your facility. Major hazard facilities are facilities that handle hazardous substances in large quantities that have the potential to cause major hazard events, fatalities, societal impact or major pollution impact. Some of these facilities may include :

- Chemical Plants

- Petrochemical Installations

- Chemical / Oil storage Facilities

- Oil and Gas Facilities (both onshore and offshore)

You may need to check with your local Regulations / authorities if you installation falls into the Major Hazard category. With the help of a Technical Safety Professional / Consultant a QRA report can be prepared for your facility, should you need one.